Ask any pest management professional what the key to successfully managing a pest infestation and more often than not, the answer will be "the inspection." The time spent looking for pest activity and the conditions conducive to pests is generally believed more important than the time spent in actual treatment applications.

Having attended dozens and dozens of conference presentations and training sessions, I’ve heard speaker after speaker state the need to "make a thorough inspection." When you teach a new professional to "make a thorough inspection," does that confuse him or her? What exactly does "thorough" mean? Should a professional inspect every crack and square inch of the infested room or building? Is that what "thorough" means? Because service professionals (and sales professionals) need to be efficient in the use of their time, it may be more advantageous to teach them how to conduct effective inspections. This article will discuss the factors and components involved in effective and efficient inspections.

TYPES OF INSPECTIONS. A pest professional servicing residential and commercial customers faces a different situation each time he or she enters a building. Therefore, it is understandable that different types of inspections are involved in successful pest management. The execution of each type differs with that type’s goals as well as with the type of pest involved.

Initial Survey. When a sales or service professional first enters a home or business, an initial survey inspection is necessary to become familiar with the structure, to determine the source(s) of the current infestation and to identify possible contributing conditions. Such a survey is made more efficient by careful questioning of the customer as to areas of pest activity, past water leaks, past pest control efforts and similar information.

Active Infestation. As part of an initial survey or in response to a current customer’s call about an infestation, one would conduct an inspection to pinpoint the source(s) of pest activity. The identity of the pest will be critical in finding the source(s) quickly as each pest has its preferences for living conditions.

Regular Service. When a service professional arrives for routine service, the customer may say that no pests have been seen. That doesn’t mean, however, that pest activity is absent. After all, customers hire their pest professionals to find and prevent infestations before they become established within the building. In many respects, this inspection type is the most difficult because with the absence of a clear target pest, the professional engages in "prospecting" for activity. The past pest history of the building is helpful in determining where to spend time as is identifying key sites where pest activity could be located or where pests could enter. For example, in a restaurant, areas that always need to be checked include the salad bar, waiter stations, stoves and the dishwasher area. Also, in a restaurant, although the manager may indicate not seeing pests, the kitchen workers generally prove to be a good source for pinpointing pest activity.

Sanitation. In food-processing facilities and warehouses, pest professionals may be asked to provide a report on sanitary conditions that might contribute to pest activity. Such inspections require familiarity with the building and its processes, and at least some experience in general manufacturing programs and pest/sanitation interactions.

Quality Assurance. Some progressive pest control companies offer QA audits for customers, especially those involving large structures. Such audits help ensure the customer is receiving services that both meet their expectations and the minimum requirements established in the service agreement. QA audits check on the service professional’s work and gauge the customer’s satisfaction with the service.

Mystery Pests. Occasionally, reports of one or more persons receiving "bites" are called in by a customer. In such cases, the pest professional must first determine if any biting pests are actually present. This is usually accomplished through the use of monitoring traps and visual inspections. More often than not, no biting pests are found and an environmental cause of the "bites" is the likely culprit.

INSPECTION TOOLS. Depending on the situation, a pest professional may need many tools handy to conduct an effective inspection. Some tools may be carried on the truck at all times; others may be available at the office in the event they may be needed. Tasks such as sanitation in a food-processing facility may require a considerable variety of tools. The point here is that the tools need to fit the job at hand and the technician’s experience and the particular situation determines what tools might be needed. It is likely best to describe and list inspection tools based on your intended task.

One’s brain and experience are likely the key tools for effective inspections. Being able to think through the problem and make quick decisions on where and how to look for pest activity and its contributing conditions is invaluable. Reference books are also a key component of the thinking process because no one knows it all or has seen it all.

You need to see. Pests typically live in dark and cryptic environments and a bright light is necessary. A myriad of different flashlights are now available and range from bright rechargeable flashlights to long-lasting LED lights. From headlamps to lights that clip on a hat to different UV lights, one might keep numerous types of flashlights available.

Another "seeing" tool is an inspection mirror. This tool permits technicians to see into places and corners where their head simply does not fit. Glass mirrors are OK for most jobs, but food plants require the use of polished metal mirrors.

Two optional tools for "seeing" may be a small pair of binoculars and a laser pointer. Binoculars come in handy for inspecting areas high above the ground. A laser pointer is handy in pointing things out to the customer, especially those sites high up in the rafters or beams.

Borescopes or similar devices are useful, when available, for peering into walls, beneath slabs or other impenetrable spaces.

You need to identify. Positive identification of the pest involved is important for an effective inspection. A magnifier of some type is necessary for small pests and reference ID books or guides are helpful as well. If the professional is unable to identify the pest in the field, collection vials are handy to contain and transport pest specimens back to the office, but in a pinch any container will do. Zip-top bags make handy pest collection devices.

You need to protect yourself. Pest management services are relatively safe tasks, but professionals sometimes need to venture into areas where personal safety could be an issue. Loud areas require ear plugs or ear muffs. Hard hats are needed in crawlspaces, attics and in most all manufacturing facilities. Safety glasses or goggles are necessary in many environments, as are protective gloves. Regular coveralls or even protective Tyvek® suits may be needed for dusty or messy areas. Respirators, possibly fitted with HEPA filters, may be needed in some situations (e.g., enclosed areas where mice, birds or bats have been abundant). Knee pads may also be helpful in some cases.

You need to have access. A variety of hand tools are helpful in accessing hidden areas within equipment or walls where pest activity might be found. Spatulas, picks and putty knives come in handy in pulling or scraping out debris from cracks to see if pests are harboring in them. An electric screwdriver can be invaluable when numerous screws must be undone to access behind outlet plates or panels on machinery.

You need to chase. When dealing with cockroaches and a few other pests, a pyrethrins flushing agent is helpful. In those cases where a flushing agent cannot be used, moving air can chase insects into the open from hidden harborages.

You need to listen. Questioning customers or workers carefully can provide a ream of information that can help focus the inspection. A simple stethoscope can be used to hear carpenter ants, bees or even rodents within a wall. Electronic stethoscopes or other audio-enhancing devices may be used depending on the availability of the tool.

You need to document. Certain basic information needs to be recorded in a report for the customer. More detailed information may increase the value of the service to certain customers. Report forms, graph paper, clipboards and colored pens are useful inspection tools. Some progressive pest professionals are using palm PC devices to record findings during inspections.

A digital camera can be useful if the customer permits photos on their property. Photos can increase the clarity of inspection reports by giving the customer a visual of the area in question by pointing out pest activity or a condition that needs to be corrected.

You need to carry. Of course, all these tools need to be available for use, so a variety of tool belts or pouches as well as carrying kits can be purchased.

EFFECTIVE VS. THOROUGH. When someone is instructed to make a "thorough" inspection, what does that mean? Imagine a service professional arrives to perform a service at a hotel. Does every room need to be inspected? Does every single little crack need to be checked? Does furniture need to be dismantled and all interior areas looked at? Does a specific amount of time need to be spent on the inspection?

My belief is that it is far more important to be effective than thorough. No one has the time to spend checking every square inch of a structure for a particular pest. To be effective, inspection time is far better spent focusing on where the target pest is most likely to be found. After all, the customer is most concerned with the pests they’ve been seeing, right?

Here’s an example. I once was asked to help with an American cockroach infestation at a hospital. The cockroaches were regularly being seen inside — not a lot, just one here, one there. The service professional continued to look in the general area of the building where the insects had been seen, but despite several attempts, he wasn’t having much luck. Knowing this cockroach’s preferences, I asked about, then checked likely harborage areas such as a nearby basement and boiler room — no cockroaches. I then decided they might be coming from outside. About 25 feet from the building was a storm drain. Inside were 200 to 300 American cockroaches with a drain line leading directly into the building where the pests were being seen.

"Inspection" is only half the task when looking for pest harborages. Inspecting means "to observe," "to detect" or "to recognize." Once one determines a "site of interest," then an investigation is warranted. "Investigation" means to "dig in," "disassemble," "gather clues" and "make decisions." In the case above, my inspection outside revealed the presence of the manhole. I then needed to investigate to confirm the sewer was the source of the infestation.

I like to say that inspections need to be "entomo-LOGICal," meaning that the type of pest involved determines much of how and where you conduct your inspection. Each pest has its biological quirks, its preferred living conditions and its own specific habits. Knowing the identity of the target pests provides information on where to focus the inspection by finding and investigating those sites in and around the building where the preferred conditions are located.

Here’s an example: Ants were being seen on a desk of a second floor cubicle in an office building. They were acrobat ants, which prefer to nest within wood. But wood is not a significant construction component of a steel and glass office building. Therefore, I spent no time inspecting inside except to identify the ants. I immediately ventured outside and located a trail on an inverted corner running up the building. Turning to look outward, I saw a large tree about 60 to 70 feet away from the building — the only "wood" anywhere nearby. Going immediately to this tree, I found large trails of acrobat ants foraging up the tree. I then traced this trail through the grass, onto and up a sidewalk and to the inverted corner. It took more time to walk down the stairs to get outside than it did to discover the source of the infestation simply because I knew my target pest preferred wood.

A second case occurred when checking rodent traps in a food distribution warehouse with a service professional. During the course of this task, we found phorid flies trapped on the glue traps inside the Tin Cats along one wall. In such cases, I know that this fly shows up in warehouses when food items become damaged as the pallets are stacked. It took about four to five minutes of going up and down stacks to find cans of chicken broth that had been dented and were leaking. The area had numerous fly larvae, pupae and adults.

Not all inspections go this easily. I’ve been involved in situations where the source took hours, even days, to discern. A key case that stands out to me involved tiny beetles showing up by the hundreds in the "clean room" of a pharmaceutical facility. In fact, three different beetles were involved: plaster beetles of the family Lathridiidae, a fungus beetle in the genus Silvanus, and rove beetles from the family Staphylinidae. The first two beetles are fungus feeders, which meant that a source of constant moisture was present supporting the growth of molds. The rove beetles were predators that likely were feeding on the fungus beetles.

We started the "inspection" by placing double-sided tape along the edges of all walls to determine if beetles were emerging from under the wall (they weren’t) or were coming from the middle of the room (they were). We also placed two insect light traps in the false ceiling above the room. The ILTs were located back-to-back in the center of the ceiling. I wanted to see if there was a particular side of the ceiling void from which the beetles were originating (there wasn’t). It was actually in the ILTs that we discovered that rove beetles were also present.

We then proceeded to check for beetles in neighboring rooms and above the ceiling. We also put ILTs outside to see if the same species of beetles were present outside at night. I inspected the exterior soffits nearby the affected room and pulled out bird nests and other debris but found no beetles. (It is important to note here that although I wore a dust mask, I should also have worn a disposable coverall as I developed a contact dermatitis rash after being up in the soffits.)

In short, it took many days to work this "process of elimination." I ruled out the exterior, the walls, the false ceiling and neighboring rooms as possible sources. Early on, I was convinced the flat roof above this room was involved, but I needed to work the process because coring a flat roof can be expensive. Ultimately, coring the roof was the last option and subsequently revealed the source as the waterproofing layer within the roof was improperly installed and had permitted moisture to collect and molds to grow. Repairing the roof eventually solved the infestation.

The point made by these examples is that an effective inspection keys on looking for those sites in and around a building where the preferred living conditions of the target pest may be found. In some cases, one must start by eliminating the most likely spots and working until the source(s) is found. To be effective, keep the following in mind:

1. Microenvironments. Insects and other arthropods live in an environment different from ours. Theirs is a miniature world where the humidity, moisture, and temperatures can vary significantly from those we feel in the air far above the ground or floor. In my experience, looking for sites where moisture might accumulate is where most pests will be found. So when inspecting, the key sites to investigate are those that involve "structure" that supplies the protective shelter and also holds moisture.

2. Interrogation. Customers can be a wealth of information — if one asks the right questions. Customers may provide information about the construction of the building, past water leaks, where pests are most seen, and other helpful tips. In commercial buildings, it is often better to also talk to the business’s employees not just the contact person. Maintenance men and engineers are helpful regarding a structure’s history while even the dishwasher or cooks in a restaurant can point out where they’ve seen cockroaches.

3. Floor Plans. The larger the building, the more helpful floor plans can be. Pest activity — both past and present — can be plotted floor-by-floor and may offer "big picture" clues as to areas that might require closer investigation.

4. Structural Guidelines. Most pests are like people — they like to use guidelines during their travels. Humans use trails and roads while pests use edges and corners. Inspecting along guidelines often reveals the pests themselves or signs they’ve left behind.

5. Monitors. Monitoring traps are commonly overused in pest management. Such traps are often placed where pest activity is not likely or in high risk areas where visual inspection will be necessary anyway, such as under a stove or dishwasher in a kitchen. Monitors may be used for one of four reasons:

(a) to detect the presence of pests,

(b) to identify the offending pests that are present,

(c) to determine the extent of an infestation, or

(d) to pinpoint an active harborage.

In the first two cases, maybe one to three traps may needed; in the latter up to several dozen may need to be placed, depending on the size of the building or the situation. In one case in a manufacturing facility where brown recluse spider "bites" had been reported, I used about 400 insect sticky traps to determine if brown recluse were actually present and if so, the severity of the infestation and which areas of the building were affected. (It turns out, not a single brown recluse spider could be found.)

I like to use monitoring traps in hard-to-inspect areas that are fairly high risk for pest activity. For example, a panel on a large cooler might have many screws in it that take valuable time to remove. By placing a Victor Roach Pheromone trap inside such compartments, it makes easier to check the area the next time. If cockroaches do infest the compartment, one or more will likely show up in the trap. The next time I go through the trouble of removing that panel again, a quick look at the trap lets me know immediately if I have to take more time checking and treating inside. No insects means I can close up the panel and move along.

SUMMARY. Inspections are at the core of what we do as pest management professionals. In fact, we might better term ourselves "pest inspectors" or "PIs" for short. By taking into account a pest’s preferred living requirements and habits and applying that knowledge to the situation at hand, combined with information provided by the customer, one can be more effective in resolving infestations and being more efficient with his or her time.

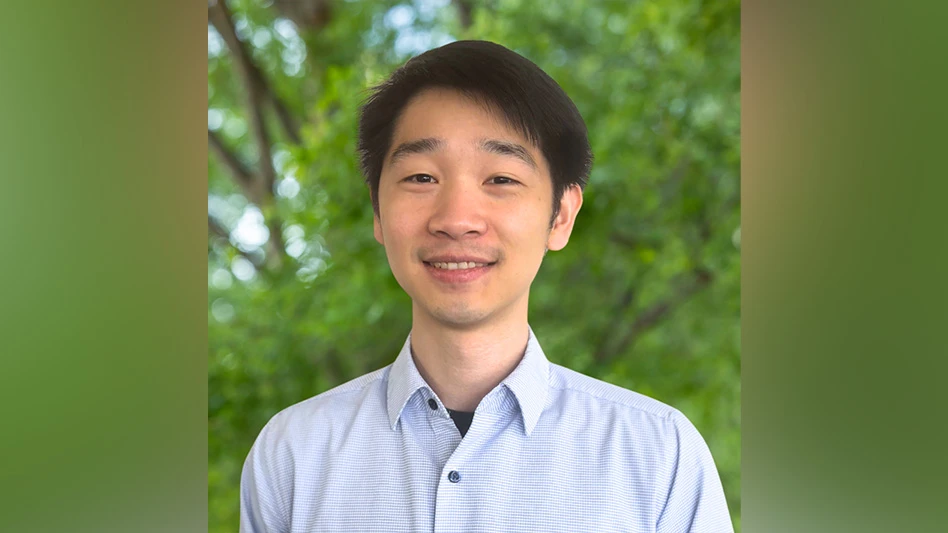

The author is a board certified entomologist and manager of Technical Services, Terminix International, Memphis, Tenn. He can be reached at shedges@giemedia.com.

Explore the September 2005 Issue

Check out more from this issue and find your next story to read.

Latest from Pest Control Technology

- Suburban Pest Delivers 117 Books Through Its Book Drive

- Anchor Pest Discusses Billboard Marketing

- MGK Expands Coverage Through New Appointments

- Pest Pros Acquires Eagle Pest Control

- Clicki Referrals Partners With Denaro AI

- Beyond the Pest | Ep. 9 — Dr. Stan Cope

- Pro-Shield Nsulation: A New Frontier in Pest Control

- Pat Hottel Reflects on 90th Purdue Pest Management Conference Theme and History