Bed bugs are an incredibly difficult pest to control because they are so good at hiding in tiny cracks and crevices. Today, a person’s home can offer a bed bug many hiding locations, such as books, electronics, clothing, knick-knacks and toys. Many modern bed bug populations are also highly resistant to the insecticides registered for their control. Because bed bugs in a home can be difficult to access and have a proven ability to develop resistance to a wide range of insecticide classes, homeowners and pest management professionals have been searching for novel, non-chemical methods of killing bed bugs in household items.

Bed bugs are an incredibly difficult pest to control because they are so good at hiding in tiny cracks and crevices. Today, a person’s home can offer a bed bug many hiding locations, such as books, electronics, clothing, knick-knacks and toys. Many modern bed bug populations are also highly resistant to the insecticides registered for their control. Because bed bugs in a home can be difficult to access and have a proven ability to develop resistance to a wide range of insecticide classes, homeowners and pest management professionals have been searching for novel, non-chemical methods of killing bed bugs in household items.

Heat exposure is an effective way of controlling bed bug infestations. The recognized thermal death point (full mortality in one minute) for all bed bug life stages including eggs is 50ºC (122ºF) (Kells and Goblirsch 2011). Heat can be used to treat whole rooms or entire structures (Cooper 2011). After completely sealing specific rooms or apartment units, heat treatment technicians will set up heaters (electric or propane) and fans (to circulate the heat) in the treatment area. Temperature sensors are placed in the hardest-to-heat areas, such as between mattresses, underneath seat cushions and inside items where air flow is limited. The goal of the heat treatment is to make sure the temperature at each sensor has reached the bed bug thermal death point. While whole-unit heat treatments have been proven effective, they must be performed by a reputable company with technicians trained to monitor the temperatures in the treatment area so the bed bugs are killed. Technicians also should be trained to avoid damage to items inside the home, particularly those items that might be sensitive to heat. In addition, they should be well trained in state laws regarding the management of overhead sprinkler systems.

In addition to whole room heat systems, bed bugs’ susceptibility to heat has allowed us to use common household dryers to kill bed bugs in infested cloth items (Miller 2009a). The high heat setting on most household dryers easily reaches the thermal death point for bed bugs and will kill all life stages as long as the dryer is loosely packed with enough room for air flow (Potter et al. 2007, Naylor and Boase 2010).

| PRODUCT | BENEFITS | CHALLENGES |

| BugStop HotHouse |

|

|

| Bed Bug Baker |

|

|

| ZappBug Room |

|

|

One of the more novel approaches to bed bug heat treatment is the use of heat chambers or portable heating units to treat infested furniture, electronics and other household items. A group of bed bug researchers at the University of Florida developed an inexpensive “do-it-yourself” heat chamber that was constructed using common materials that could be purchased at hardware stores (Pereira et al. 2009). Using thermocouples, the researchers monitored the temperature within the heat chamber and the chamber was able to reach the thermal death point for bed bugs within six hours. While heat chambers require more time to reach lethal temperatures than clothes dryers, more and larger items like furniture, books and electronics can be treated inside of a heat chamber (Miller 2009b).

In 2014, at NPMA PestWorld in Orlando, Fla., three new, commercially available heat chambers were on display from manufacturers. With permission and assistance from these manufacturers, we evaluated all three chambers to determine their efficacy, set-up and run time, ease of use and overall cost. We also were able to determine the advantages, challenges and best uses for each chamber. The three chambers evaluated were the BugStop HotHouse (AmCan Products, Lynbrook, N.Y.), the Bed Bug Baker Lodger Model (Bed Bug Battalion, Cape Girardeau, Mo.) and the ZappBug Room (ZappBug, Seattle, Wash). Each chamber was unique in its design, size and cost (see Table 1 below).

Shipping and Accessories.

Because the manufacturers were located in three different regions of the United States, we thought it was important to look into the differences associated with acquiring each chamber. The BugStop HotHouse is manufactured in Lynbrook, N.Y., where it can be shipped throughout the country for about $235. Our chamber arrived in a large square box, weighing 107 pounds. Inside the box were two large yellow bags containing the chamber, the heating unit and other supplies.

The Bed Bug Baker is manufactured in Cape Girardeau, Mo., and costs between $150 and $300 to ship, depending on your location. Our chamber arrived on a 172-pound freight pallet. Because of the size of the pallet, the pallet needed to be unloaded by the freight truck, but one could also use a forklift. Inside the pallet box, the Bed Bug Baker was stored in six large canvas bags.

The ZappBug Room is distributed from Seattle, Wash., and is shipped throughout the U.S. for no cost (free shipping). This chamber arrived in two boxes, weighing 48.5 pounds and 41.8 pounds, each of which contained a large storage bag.

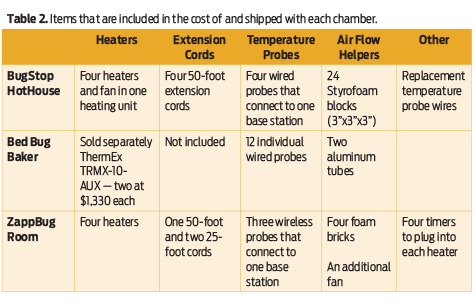

Once we had received all three chambers, each was unpacked to determine exactly what was included (see Table 2 below). The BugStop HotHouse is essentially a large inflatable bag, made of insulated fabric, with a reinforced zipper. The chamber is intended to be zipped up around its contents, while the heating unit forces hot air inside, creating a positive pressure. The heating unit has four separate heating elements, each of which needs to be plugged in using one of four 50-foot extension cords (included). Depending on the number of available electrical outlets and circuits, the heater can operate using two to four of the heating elements. The heating source is placed at one corner of the chamber and two air hoses (input and output) circulate the heated air throughout the chamber interior. The chamber also includes four temperature monitoring wires that connect to a single base station, located at the front of the chamber. These long copper wires are intended to be pulled into the chamber and placed deep inside furniture and other items to monitor the interior temperatures. Finally, 24 Styrofoam blocks (included) can be used as spacers between furniture and other items to facilitate air flow during heating.

The Bed Bug Baker has an acrylic pipe frame that is surrounded by two separate layers of very dense, insulating fabric material. For the heat source, the manufacturer of this chamber recommends using two ThermEx Chromalox heaters (combination heat and fan units; Chromalox, Ogden, Utah), which are sold separately. The heating units are to be placed in opposite corners on the inside of the chamber. The Bed Bug Baker comes with two aluminum hoses (5-inch diameter) to help direct air flow throughout the chamber. This chamber also includes 12 wired, battery-operated, indoor/outdoor thermometers for monitoring interior temperatures.

The ZappBug Room has an aluminum, “pop-up” style frame that is covered with a single layer of insulating fabric. The fabric is attached to the frame with Velcro and zippers. Four small electric heaters are set outside of the rectangular chamber, one at each corner. The heaters take air from outside of the chamber, heat it and force it into the chamber creating positive pressure. Each of the heaters is paired with a timer. The timer can be set to shut off the heater after a selected amount of time (up to eight hours). The ZappBug Room comes with two 25-foot extension cords to distribute electricity to different circuits. An additional electric fan (included) is intended to be suspended on the interior of the chamber to increase air flow. The ZappBug Room also comes with three wireless temperature sensors to monitor temperatures inside treatment items.

Chamber Evaluations.

All evaluations took place at a local women’s shelter, which had an active bed bug infestation. The women’s shelter consisted of six dormitory-style bedrooms that contained mattresses, bed frames, nightstands and dressers. There also was a community living room with several couches, arm chairs and bookshelves, as well as a community kitchen and dining area. The shelter served as a temporary home for both women and children, who typically arrive with their own personal belongings, such as clothing, books, toys and electronics. The shelter was an ideal location to evaluate the chambers because of the many items that could be heat treated, including furniture and personal belongings. Further, we were able to help remediate the active infestation in the building by treating as many infested items as possible.

Each chamber was run five separate times. Each run involved chamber set-up, filling it with furniture and personal belongings and heating all items to the bed bug lethal temperature. In each evaluation, five replicates of 10 sentinel bed bugs (captive, mixed sex and life stage) also were placed inside the chamber among the items to confirm bed bug death. For each replication of each chamber, we recorded the set-up and run times, all temperatures and the number of people involved in the set up.

How Long was Set-Up?

In our evaluations, the first step was to assemble and load the heat chambers. In each of the five replications for each chamber, the set-up process was timed (see Table 3 below). As expected, the set-up time for the first replicate was always longer than for subsequent replicates, because we were not yet familiar with the assembly instructions. For each chamber, two to three people were required for the set-up process, though they were primarily needed for moving large furniture into the chambers. Factors that influenced the set-up time included:

- The time required to load larger furniture items into the chamber.

- The number of chamber components to be assembled, i.e. interior framework, insulating fabric layers, the number of temperature measuring devices and the number of heaters.

- The time required to make sure the items in the chamber were well distributed to accommodate optimal air flow.

- The time required to place the temperature monitors and sentinel bed bugs throughout the chamber.

Heaters and Circuits.

All three heat chambers use electric heating units. A major concern with the electric heaters was whether or not they had the “firepower” to heat the dense items and furniture inside each chamber. The heating capacity of electric heaters is often measured in watts, where an efficient heater operates above a 10:1 ratio of watts to square feet. Using the recommended heaters and the dimensions for each chamber, we determined that the associated heaters did have the firepower to efficiently heat each chamber. Keep in mind, however, that the chamber’s goal is not just to heat the space inside the chamber, but to heat potentially infested items to the bed bug lethal temperature. Depending on the amount and type of items inside the chamber, you might need to use a chamber with more heating capacity and firepower (watts per square feet).

A second concern was the electrical capacity of the building. Would the older building that houses the women’s shelter be able to meet the electrical requirements of each chamber? Because all of the chamber heating units run off of electricity, it was important to know the voltage required for each chamber, so as to not overload the circuits. The instructions for each heat chamber indicated which heating units needed to be plugged into separate circuits.

Run Time: How Long?

After conducting five replications with each heat chamber, we were able to report the mean run times and the maximum observed temperatures. In all replicates for each chamber, the thermal death point for bed bugs was reached in less than six hours. All of the sentinel bed bugs, and presumably any bed bugs in the furniture, were killed. While the ZappBug Room heated more slowly than the BugStop HotHouse and the Bed Bug Baker, the temperature monitors still reached over 135ºF in less than six hours.

Benefits/Challenges.

Overall, each of the three chambers performed very well in our evaluations. All reached the bed bug lethal temperature in under six hours and killed all of the sentinel bed bugs. And while each of the three chambers offered its own unique advantages, there were several additional aspects that one would want to consider before purchasing a chamber. (See table on page 96 for benefits/challenges.)

Best Uses for Each.

While each of the chambers that we evaluated was effective, the BugStop HotHouse, the Bed Bug Baker and the ZappBug Room are unique in design and may be used most efficiently in different situations. The BugStop HotHouse would be an ideal heat chamber to be transported between multiple apartments, where it could be set up inside infested units. This chamber is definitely the work horse of the group and easily could be used over and over to treat household items and furniture. The Bed Bug Baker would be the best chamber to use in a temporary living facility where a single room could be converted into a heat treatment area. Facilities like substance abuse centers, shelters and hospitals, where new people are frequently coming and going would benefit from having a heat chamber like the Bed Bug Baker. This chamber could remain partially set up all the time for heating furniture and personal items that may need to be treated very frequently. The ZappBug Room would be best suited for use in homes, summer camps, thermal shelters or other situations where the chamber would not be used daily, but could be set up quickly and used immediately. The ZappBug room also is easy to carry, pack away and store.

Overall, the three portable heat chambers that we evaluated are effective for killing bed bugs in potentially infested furniture and personal items, because:

- They have the firepower necessary to efficiently heat the contents of each chamber above the thermal death point for bed bugs.

- They have large enough interior volumes to heat multiple personal items and furniture at the same time.

- They can be set up and run in a wide range of locations and situations.

- They complete the job in under six hours.

The authors are with the Virginia Tech Bed Bug and Urban Pest Information Center, Blacksburg, Va.

References

Cooper, R. 2011. “Ectoparasites, Part Three: Bed Bugs & Kissing Bugs,” in S.A. Hedges and D. Moreland (eds), Mallis Handbook of Pest Control, 10th Edition, pp. 587-632. Richfield, Ohio: Mallis Handbook Company, 2011.

Kells, S. A. and M. J. Goblirsch. 2011. Temperature and time requirements for controlling bed bugs (Cimex lectularius) under commercial heat treatment conditions. Insects 2(4): 412-422.

Miller, D. M. 2009a. “Living with bed bugs.” Pest Management Professional. 77(7): 37, 39-41, 43.

Miller, D. M. 2009b. Using Heat to Kill Bed Bugs. Virginia Department of Agriculture and Consumer Services. Richmond, Va. Available from: http://www.vdacs.virginia.gov/pesticides/pdffiles/bb-heat1.pdf

Naylor, R. A. and C. J. Boase. 2010. Practical Solutions for Treating Laundry Infested with Cimex lectularius (Hemiptera: Cimicidae). J Econ Entomol 103(1): 136-139.

Pereira, R. M., P. G. Koehler, M. Pfiester. and W. Walker. 2009. Lethal effects of heat and use of localized heat treatment for control of bed bug infestations. J Econ Entomb 102(3): 1182-1188.

Potter, M. F., A. Romero, K. F. Haynes and E. Hardebeck. 2007. “Killing them softly: Battling bed bugs in sensitive places.” Pest Control Technology magazine, January 2007: 24-32.

Explore the June 2015 Issue

Check out more from this issue and find you next story to read.

Latest from Pest Control Technology

- Climate-Friendly Air Conditioning Inspired by Termites

- Pest Management Supply Opens Branch in Gilbert

- Sprague Expands California Presence with Fresno Branch

- Big Time Pest Control Expands with Sacramento Office

- The Role IPM Plays in a Rodent Control Program

- Sureguard Lawn & Pest Services Acquires R&B Pest Control

- Abell Pest Control Recognized as Top Workplace in Canada for Second Consecutive Year

- PCO Follows the Carpenter Bee Clues